Understanding the Basics

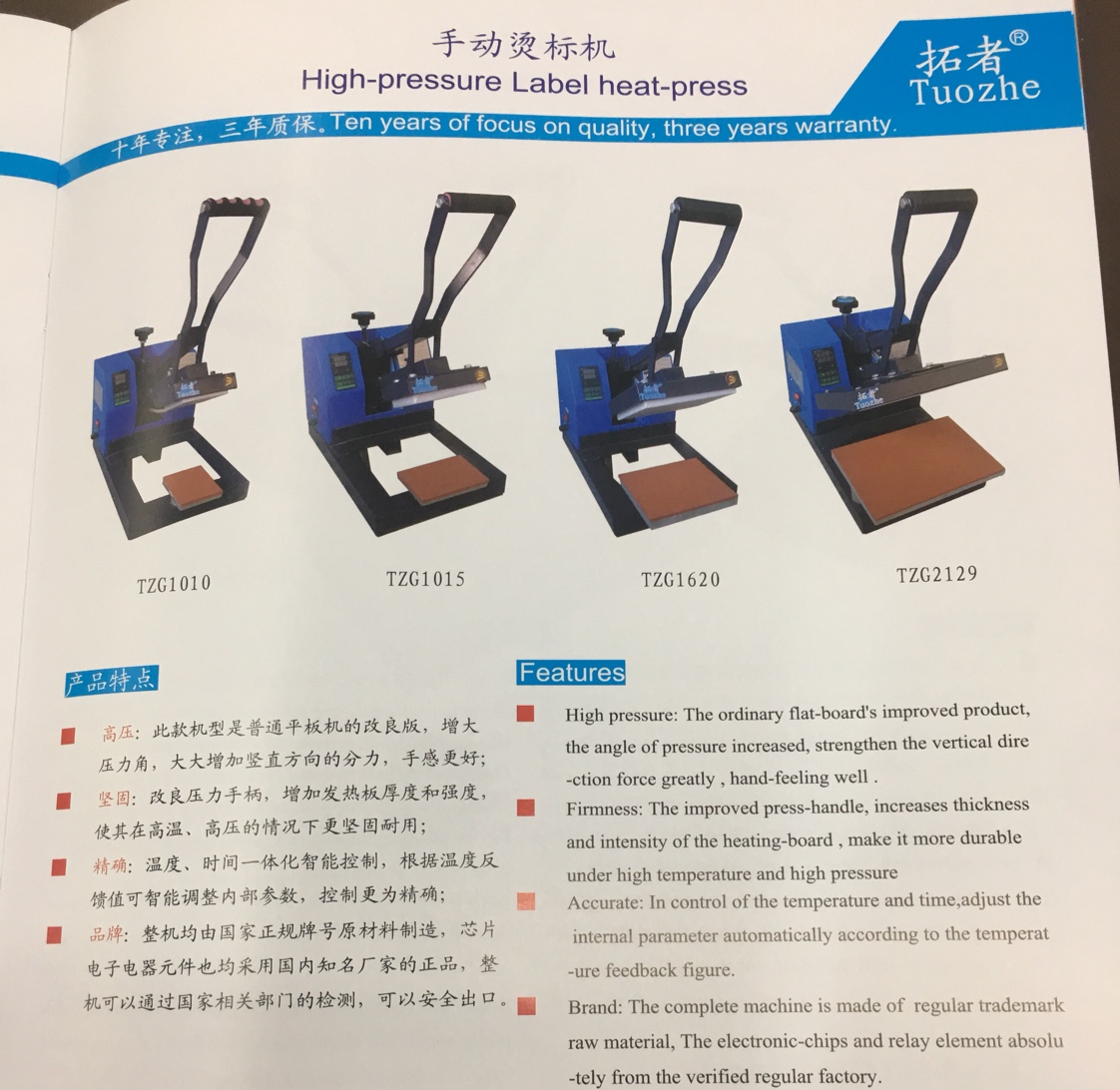

A manual ironing machine, such as the Topo 10*10 high-pressure hot stamping machine, operates through user control over heat and pressure settings to achieve desired results on fabrics. These machines often involve mechanical levers or rotary dials that allow precise adjustments.

In contrast, automated ironing systems rely on pre-programmed settings and sensors to manage the ironing process, often requiring minimal human intervention. They are designed to simplify tasks but may lack the nuanced touch offered by manual devices.

The key differences between manual and automated ironing machines lie in their operation methods, precision levels, and overall user engagement during the ironing task.

Precision and Control

Manual ironing machines provide users with detailed control over both heat and pressure. This means you can tailor the intensity precisely for various types of fabric, ensuring optimal care without causing damage. For delicate materials, this level of customization reduces the risk of burns or material wear, affording better longevity and appearance preservation.

Automated systems might not offer the same degree of flexibility. Pre-set programs can't always cater to specific needs, particularly when dealing with varied textile compositions which require bespoke handling.

Cost and Maintenance

When comparing costs, a manual ironing machine typically involves a lower initial investment than an advanced automated system. The Topo factory direct model is competitively priced at around $105, making it accessible for many users.

Maintenance for manual machines tends to be straightforward and less costly due to simpler mechanics. Repairs can often be done with basic technical knowledge and available parts, whereas automated machines may need specialized service, leading to higher ongoing expenses.

Energy consumption also favors manual models; they don't consume power continuously like automated ones, potentially reducing operational expenses significantly over time.

User Experience

Manual ironing machines boast ergonomic designs that prioritize user comfort during prolonged use. Their functionality demands active participation, which some users find fulfilling and engaging. Although there's a learning curve involved, many report high satisfaction once they master the machine’s features.

Safety is another aspect where manual irons excel. With complete control over settings, there’s reduced risk of accidental overheating or fabric damage. Safety mechanisms are often more intuitive and under the user’s direct oversight.

Versatility

Manual ironing machines excel in versatility. Notably, they handle various ironing tasks with ease, allowing fine-tuned attention to intricate details such as pleats, ruffles, and accessories. This adaptability is especially advantageous in home settings, as well as small businesses needing a reliable tool for diverse garments without switching modes or relying on preset protocols.

Environmental Considerations

From an environmental perspective, manual ironing machines tend to be more energy-efficient. Given their mechanical nature, they do not draw continuous power like electronic counterparts. They also generally have longer lifespans and consist of repairable components, meaning fewer replacements and reduced waste.

The production process for manual irons usually has a smaller ecological footprint compared to sophisticated automated machines laden with sensors and complex electronics, further mitigating environmental concerns.

Case Studies and Real-Life Examples

User testimonials highlight several advantages of manual ironing machines, citing better results in tasks demanding precision and careful management of fabric properties. For instance, boutique owners who deal with custom clothing mention how the manual approach allows superior finishes on intricate work pieces compared to automated versions.

Real-life scenarios demonstrate that manual ironing excelling in special cases—like pressing bridal gowns or ceremonial attire—where specific temperature settings, pressures, and techniques are critical.

Making the Right Choice

Deciding between a manual and automated ironing machine depends largely on individual requirements and habits. Consider factors such as your familiarity with ironing technology, budget constraints, the frequency of use, and specific garment care needs.

The long-term benefits of investing in a manual machine include lower maintenance costs, better energy efficiency, and enhanced control over the ironing process. Potential drawbacks mainly pertain to the effort required for operation and the necessity of acquiring specialized skills.

Ultimately, choosing a manual ironing machine like the Topo factory direct sales 10*10 high-pressure hot stamping unit ensures you obtain a durable, efficient, and highly customizable tool suitable for a broad range of applications.