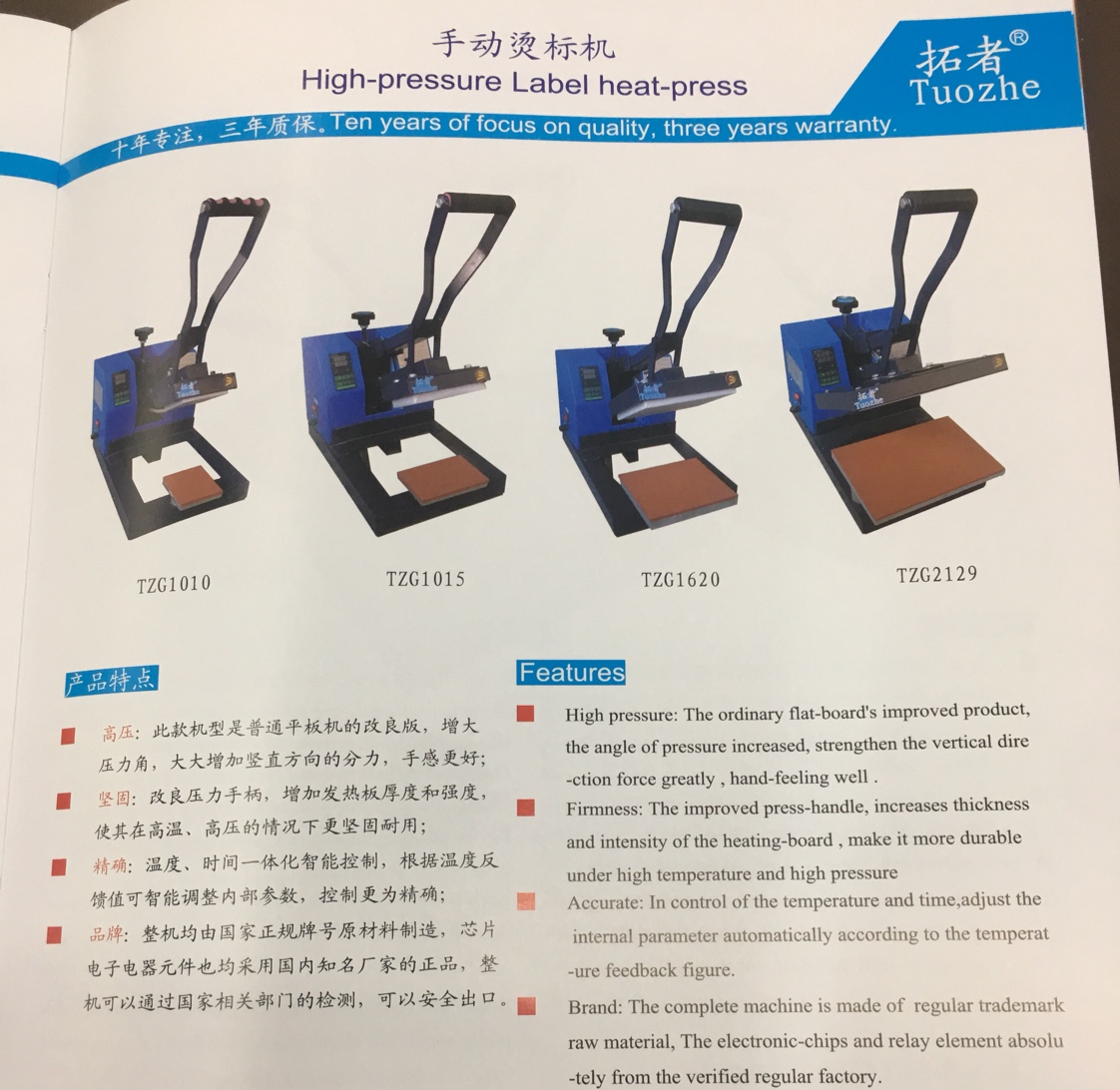

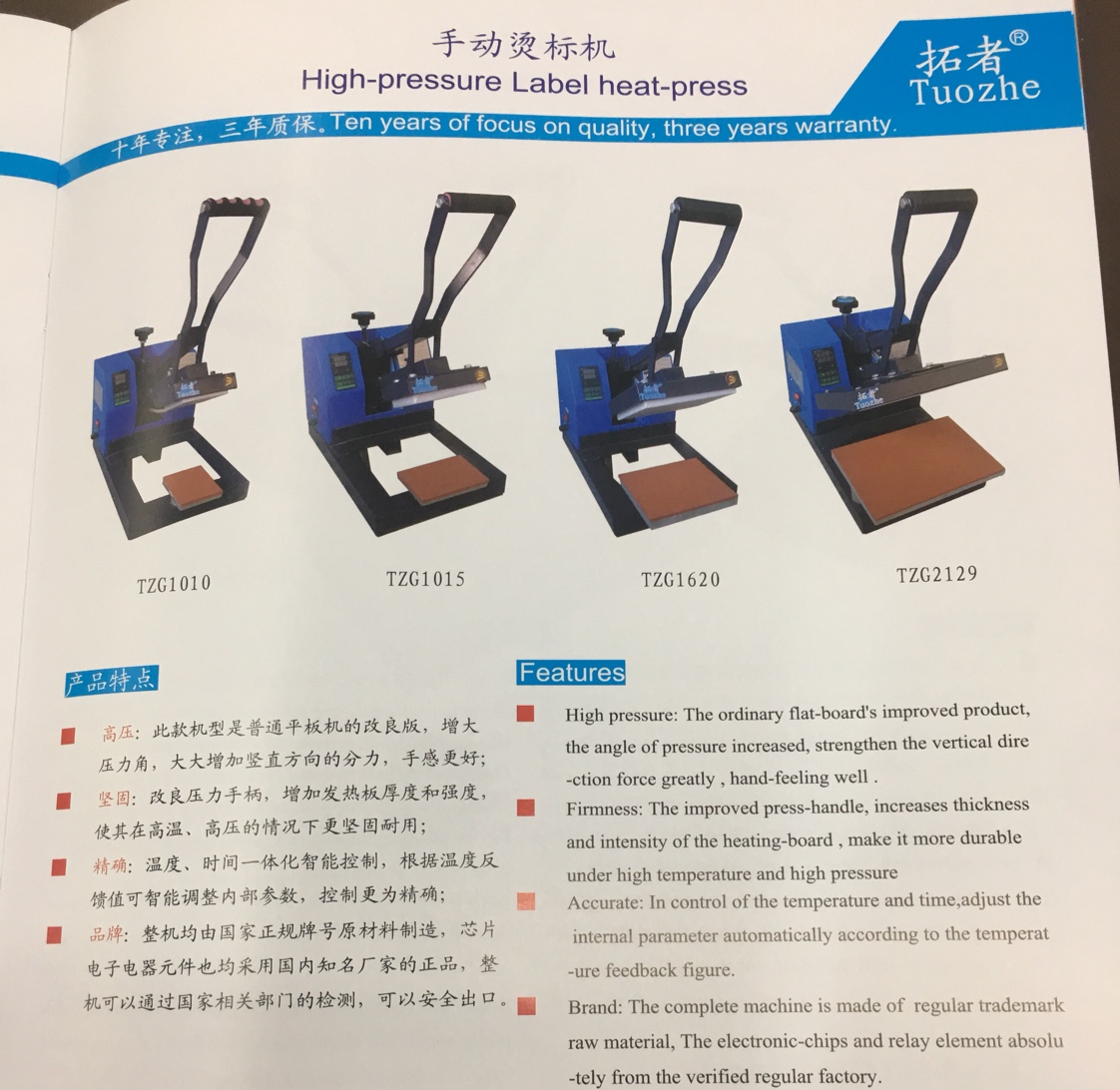

Maintenance Tips for Your Topo 10*10 High Pressure Hot Stamping Machine

The Topo 10*10 high pressure hot stamping machine is a valuable asset for any printing or manufacturing business. Ensuring its continued efficiency requires regular maintenance and care. Below are some essential tips to help you maintain this machinery effectively.

Basic Care and Cleaning

Regular Surface Cleaning: Wipe down the external surfaces of your machine with a damp cloth regularly. Using non-abrasive cleaners can help keep the finish pristine without causing damage.

Interior Maintenance: Equally important is taking care of the interior components. Clean the heating plates meticulously, and make sure to remove any debris and residue build-up that could affect performance.

Routine Inspections

Checking Electrical Components: Regularly inspect the wiring and connections of your hot stamping machine. Additionally, assess the control panel to identify any faults early on, mitigating potential hazards and downtime.

Mechanical Parts Examination: Lubricating moving parts ensures smooth operation and prolongs their lifespan. Inspect gears and belts periodically for signs of wear and tear to replace them before they cause larger issues.

Operational Best Practices

Proper Warm-Up Procedures: Gradually heating up your machine will avoid thermal shock. Consistently monitor temperature settings during use to ensure optimum performance and prevent overheating.

Optimal Usage Techniques: When positioning materials, always follow manufacturer guidelines to prevent misalignment. Avoid overloading the machine as excessive strain may lead to premature malfunctions.

Preventative Maintenance Schedule

Daily Checks: Ensure that the machine is clean before each use and test basic functions to detect any anomalies early.

Weekly Tasks: Conduct detailed inspections of critical components weekly. Calibration of pressure and temperature controls should also be part of your routine to maintain precision.

Monthly Upkeep: At least once a month, undertake thorough cleaning and lubrication exercises. Comprehensive system diagnostics help preempt major breakdowns, keeping your production seamless.

Troubleshooting Common Issues

Addressing Temperature Fluctuations: Periodically check thermostat accuracy to deal with any irregularities. Uniform heat distribution is essential, so ensure all elements work harmoniously.

Dealing with Pressure Irregularities: Verify the integrity of the hydraulic system frequently. Adjust pressure settings based on observed performance to maintain consistent output quality.

Professional Servicing and Support

When to Call a Technician: Recognize early warning signs such as unusual noises or unexplained errors. Engaging qualified service providers promptly minimizes downtime and extends the life of the machine.

Warranty and Service Agreements: Understand the details of your warranty coverage to fully capitalize on it. Utilizing service contracts provided by reliable professionals ensures steady machine health.

User Training and Safety

Educating Operators: Provide comprehensive training for new users to instill best practices from the onset. Frequent updates and refresher sessions keep staff knowledgeable about the latest techniques.

Safety Precautions: Implement proper safety gear usage and make sure emergency shutoff protocols are widely known among operators to enhance workplace safety.

Upgrades and Replacement Parts

Identifying When Upgrades Are Needed: Monitor performance metrics to recognize when components become outdated. Evaluating the cost-benefit of newer technology can save long-term costs while enhancing efficiency.

Sourcing Reliable Parts: Choose reputable suppliers to source replacement parts. This not only guarantees compatibility with your machine but also assures durable quality.

Documentation and Record Keeping

Maintenance Logs: Keep detailed records of all maintenance activities. Tracking performance metrics helps pinpoint areas needing improvement and serves as documentation for troubleshooting.

Manuals and Guides: Maintain up-to-date documentation and take advantage of resources provided by the manufacturer for effective problem-solving.

Community and Manufacturer Resources

Joining User Forums: Participate in online communities where fellow users share helpful tips and tricks. Learning from the experiences of others can provide practical insights you might not find in manuals.

Manufacturer Support Channels: Leverage direct support from the manufacturer to access official tutorials and FAQs. These channels often offer solutions tailored specifically for your model.

By following these maintenance tips, you can ensure that your Topo 10*10 high pressure hot stamping machine remains operational at peak efficiency, reducing downtimes and extending its service life.