Unveiling the Topo 10*10: A Game-Changer in Hot Stamping

Hot stamping is an advanced manufacturing process widely used across different industries for applying decorative finishes and protective foils to a variety of materials. By leveraging heat and pressure, this technique enables the transfer of metallic strips, patterns, or colors onto substrates like leather, plastic, paper, and fabric. Industries such as packaging, automotive, textiles, and consumer electronics extensively benefit from this technology due to its ability to produce aesthetically appealing and durable results.

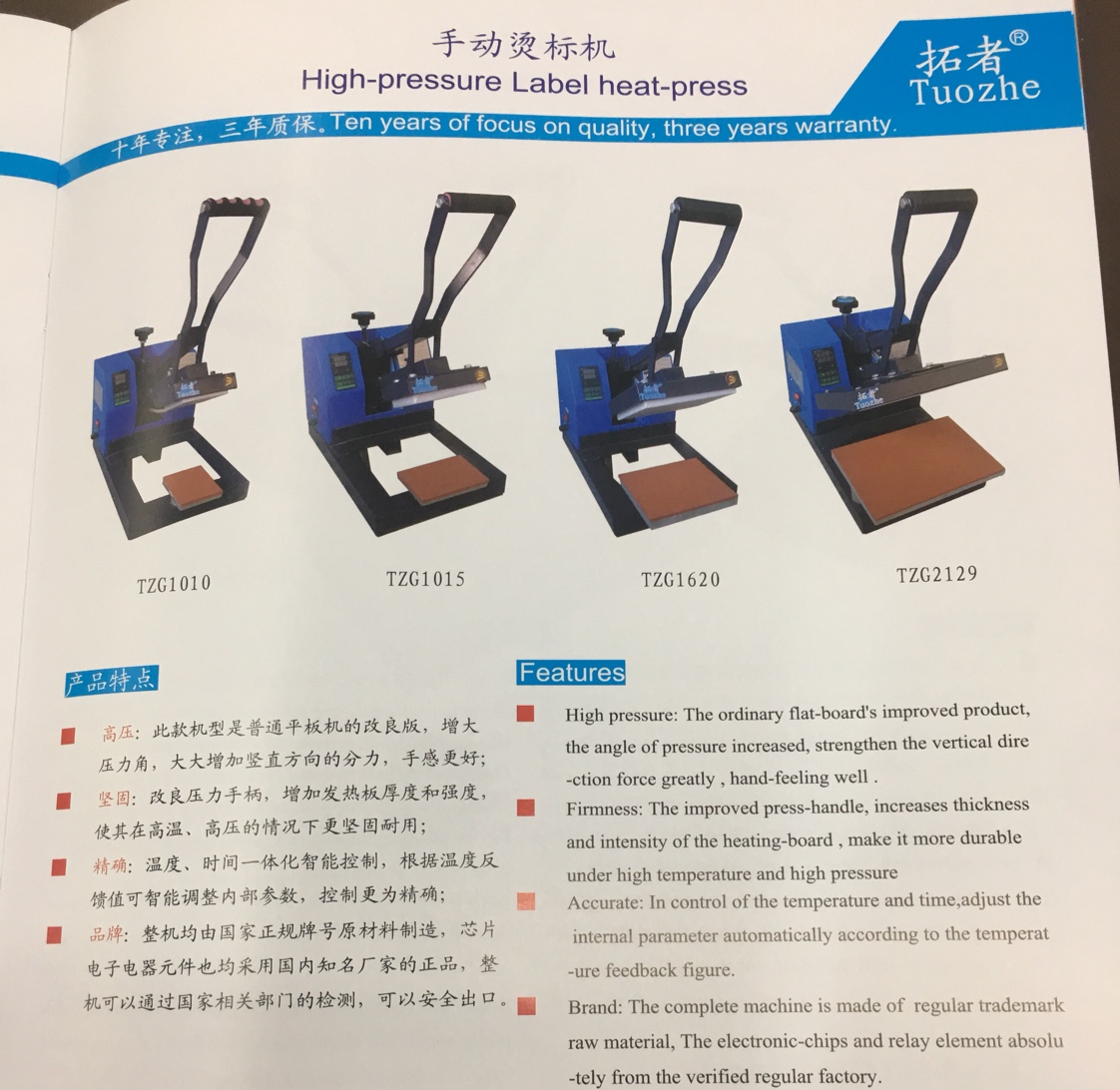

The Topo brand, renowned for its excellence in creating high-performance machinery, has introduced the 10*10 model—a device that redefines hot stamping standards. The Topo 10*10 offers state-of-the-art features meticulously designed to deliver superior performance. Built with robust construction, this compact machine ensures both longevity and reliability. Its pressure capabilities and precise temperature control set it apart as a standout performer in the market.

With ergonomic engineering and intuitive controls, operating the Topo 10*10 becomes an effortless experience. Constructed using premium materials, the machine promises durability and resilience even under demanding conditions. Technical specifications highlight significant attributes such as adjustable force and precision heating, ensuring optimal support for a broad range of applications. These elements contribute substantially to achieving flawless, professional-grade stamping results every time.

The consistency and accuracy offered by the Topo 10*10 ensure high-quality final products. Users can expect impeccable detailing and sharp impressions devoid of inconsistencies. From embossing elegant business cards to producing fashionable clothing tags, this machine caters to countless professional needs efficiently, exemplifying versatility and prowess through numerous real-world applications and impressive outcomes.

Operating the Topo 10*10 is straightforward thanks to a well-designed setup guide and comprehensive operational instructions. Setting up involves simple assembly steps followed by easy-to-follow procedures for adjusting settings according to specific project requirements. Regular maintenance, involving routine checks and periodic cleaning, enhances the lifespan of the equipment, guaranteeing sustained peak performance over extended periods.

When compared to other models available in the market, the Topo 10*10 stands out favorably concerning performance metrics and value for money. Competitive pricing coupled with unparalleled functionality makes it a prudent investment. Customer feedback underscores the satisfaction among users, praising the machine's efficiency, reliability, and consistent output quality. Excellent reviews bolster its reputation, affirming Topo’s commitment to delivering top-notch hot stamping solutions.

The adaptability of the Topo 10*10 further augments its appeal by accommodating various material types, ranging from synthetic fabrics to intricate paper designs. This flexibility endears the machine to diverse industries seeking customized stamping solutions tailored to their unique demands. Whether executing small-scale bespoke projects or mass production tasks, the Topo 10*10 seamlessly integrates into any workflow scenario.

Real-life case studies showcase the tangible benefits businesses derive from incorporating the Topo 10*10 into their operations. Companies report enhanced product aesthetics, increased branding impact, and improved customer satisfaction owing to the high-quality results delivered by the machine. Detailed examples illustrate successful implementations, providing visual testimony to its capabilities and the competitive edge it affords users.

Topo accompanies the sale of the 10*10 model with strong technical support and resources. Customers can easily contact the support team for troubleshooting assistance, access detailed user manuals, and follow instructional videos provided to help navigate any challenges faced during operation. Additionally, engaged community forums and professional networks offer platforms for users to share insights, experiences, and advice, fostering collective growth and expertise within the industry.

Investing in the Topo 10*10 secures long-term advantages including enhanced return on investment (ROI) and cost-effectiveness. High-volume outputs of consistently superior quality not only bolster the brand’s reputation but also future-proof the business against evolving technological demands. Upgrading to reliable, cutting-edge machinery like the Topo 10*10 positions enterprises strategically for sustained success and innovation-driven growth.

Purchasing options for the Topo 10*10 are readily accessible through authorized dealers or directly via the Topo Machinery Firm website. Interested buyers benefit from extensive warranty coverage and service plans tailored to ensure seamless post-purchase support. Comprehensive initial training and setup assistance are also available, equipping new users with the necessary skills to maximize the machine’s potential right from the start.

Addressing frequently asked questions, common queries about the Topo 10*10 include inquiries about compatibility with specific materials, adjustment protocols for differing pressure and temperature requirements, and recommended practices for maintaining optimal performance. Experts provide practical advice and tips, enhancing user knowledge and application proficiency. Leveraging these insights aids in fully harnessing the machine’s capacities, resulting in exemplary stamping accomplishments.